Nicola Dal Toso, CEO, Videndum, tells TVBEurope about the company’s focus on finding lower-emission alternatives to traditional manufacturing processes, and why the global electronic component shortage means it has to order parts nine months before knowing whether it will be included in the final product or not.

What impact has the pandemic and its continuing after effects had on the company’s approach to R&D and product development?

The pandemic has changed how people work in the studio. With staff working remotely, production companies invested in new technology to complete their projects.

Networks were taking advantage of robotic camera control and voice prompting to limit the number of people in control rooms. Virtual studios at broadcaster HQ’s also supported IBC installations when covering high-profile events, such as the Olympics. This allowed production to continue whilst reducing the number of people being flown to different locations.

There has also been a big focus on finding lower-emission alternatives to traditional manufacturing processes. Our team is always researching new ways to make better sustainable products that improve our customers’ workflow.

What are the biggest challenges you are facing in R&D and product development/deployment in the current landscape?

Shortages of electronic components were our biggest challenge during and after the pandemic. We must order specific parts up to nine months in advance of needing them, which sometimes can be before we know if the part will be included in the final product.

Where do you see the most opportune areas for innovation in your area of the market, and what tech/solutions will drive that development?

Environmental sustainability is a big opportunity for innovation. Anton/Bauer has just launched Salt-E Dog – the first sodium battery designed and built for the motion picture and television industry. The 9kwh battery is cleaner than fossil fuel or lithium generators and helps productions meet net-zero sustainability goals.

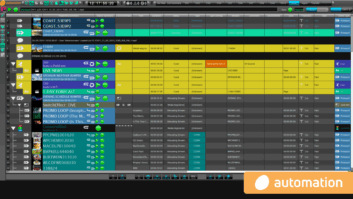

There is also an opportunity to improve efficiency for large studios and independent content creators, whilst giving them a better return on their operational and capital costs. This will come from ergonomic-focussed product design, as well as automation, software, and AI, an example being the voice control and AI-driven Presenter Tracking introduced with Vinten’s latest robotic control system, VEGA.

What are you working on currently that excites you as a product team, and what can we expect to see at IBC 2023?

We have a tradition of keeping our upcoming product launches under wraps until the launch. This anticipation adds to the excitement! Our engineering and research and development teams are designing advanced solutions for the ever-evolving motion picture and television industry. Efforts that have resulted in patented and protected intellectual property, that showcase our commitment to innovation.